At Work with Anita

Using the Anita

For at least two years in the early 1960s the ANITA was the only electronic desktop calculator available world-wide and, since the price was competitive with the electrically-driven mechanical calculators of similar capabilities, it sold very well.

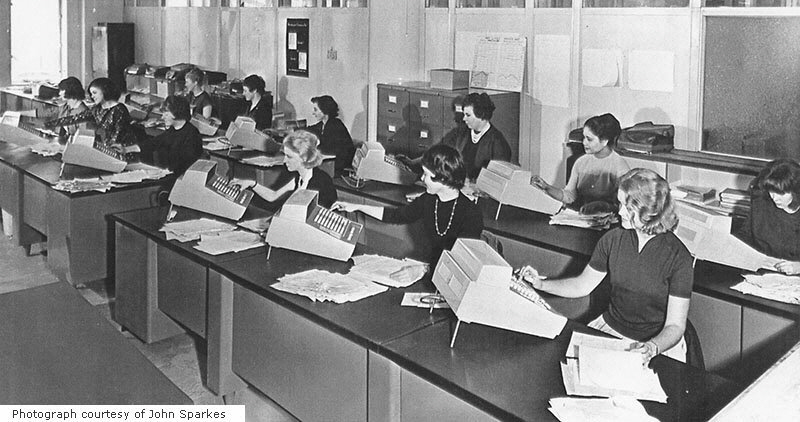

Captioned: "The world's first electronic desk calculator, the Anita Mk.8, in use in the accounts department of Selfridges Ltd., the London department store, circa 1963."

Thanks to John Sparkes for kindly providing the photograph.

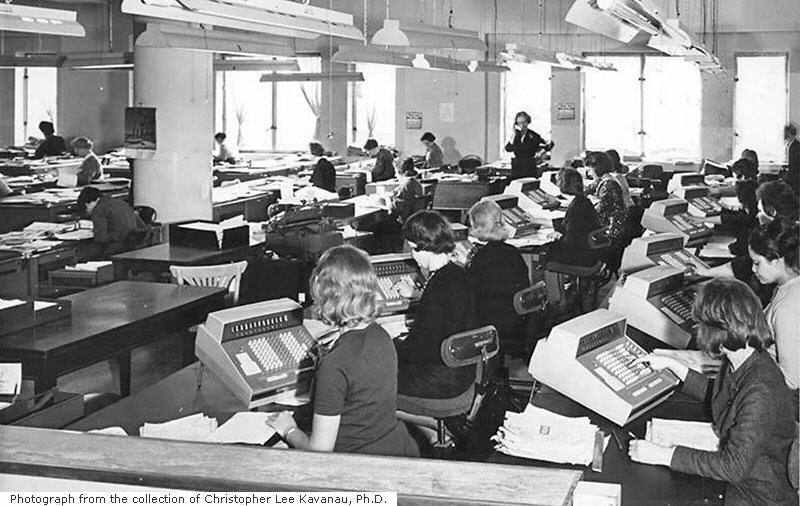

Captioned: "A class in progress at a Sumlock Comptometer Training Centre. The machines seen in this photo are Anita electronic desk-top calculators, widely used by banks and other concerns throughout Britain and also by

many firms abroad."

Thanks to Dr. Christopher Kavanau for kindly providing this image.

From a high-resolution scan of the original photograph Dr. Kavanau has been able to examine a calendar on the wall at the back and

determine that the photograph was taken in March 1963.

The two publicity photographs above pose a conundrum, as pointed out by Dr. Christopher Kavanau. They both appear to show the same people in the same place on the same occasion, but one is captioned "accounts department of Selfridges Ltd." and the other "Sumlock Comptometer Training Centre".

After considering that the photographs do appear to show the activity of a typical accounts department and that the architecture of the room with the large round column resembles that in photographs of other departments at Selfridges, we have come to the conclusion that the scene actually shows the accounts department at Selfridges. Though we do not know why the second photograph is misleadingly captioned the Sumlock Comptometer Training Centre.

Operators converting from mechanical machines of the 'Comptometer' type to the new electronic ANITA calculators often complained initially that the key stroke was too light and did not give the feel of the mechanical machine. Also, they missed the noise of the mechanism which indicated that the calculation was taking place and went quiet when the calculation was completed.

Marketing the ANITA

Bell Punch had a world-wide sales organisation and the ANITA calculators were marketed in many countries. Grant Geen recalls:

"I worked in the

Export Department of Bell Punch from 1955 to 1961. In May 1961 Mr B.C. Bell, the Export Manager, and I traveled by train from Liverpool Street station, London, to Moscow in the U.S.S.R [crossing the North Sea by ferry], each

of us with an ANITA on his lap. We were so concerned with their fragility that we scarcely let them out of our grasp ... ... I'm sorry to say that the Russians never actually ordered an ANITA."

An ANITA being demonstrated, at a British trade fair in Moscow in the early 1960s to Nikita Kruschev, the premier of the U.S.S.R, and Anastas Mikoyan, on the left, the minister for trade.

Manufacturing the ANITA

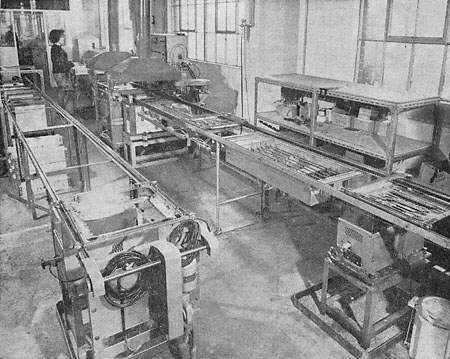

The ANITA calculators required many precision mechanical components and electronic circuit boards. To cope with this increased manufacturing requirement, advanced production techniques were introduced into the factories in Portsmouth, on the south coast of England, into which Bell Punch calculator manufacture had expanded. One such technique was the flow-soldering line for electronic circuit boards, pictured below.

Flow-soldering line for soldering all the components to ANITA electronic circuit boards in one operation lasting a few seconds.

Servicing the ANITA

Bob Ward worked for Sumlock from around 1965 to 1970 on field repair of ANITA and associated equipment based in Wolverhampton:

"The ANITA Mk 8, Mk 9 and Mk 10 were something to

behold, the Mk 9 was a development of the Mk 8 to include automatic decimal point while the Mk 10 was simply a Mk 9 with pounds/shilling/pence conversion.

The Mk 8 had 10 valves ECC82 (or 83?) and ONE transistor only! The main pulse generator was a device called a "Dekatron" while the main computing circuitry consisted of logic gates which used combinations of selenium diodes and pull up resisters to calculate using 9's complement arithmetic, the registers and Nixie displays were all driven by "trigger tubes" (neon discharge devices that operate somewhat like thyristors).

One of the main problems with the machine was that the high value resistors (19 meg ohms) used to prime the trigger tubes frequently altered to a much higher value causing erratic operation, and there were many, many 19 meg resistors in a machine! In operation with the covers off the machine was a sight to behold with dozens of flickering lights as the trigger tubes performed the calculations. Of course at the end of calculation you had to manually set the decimal point. Sumlock also made a Mark 12 machine which was fully transistorised (not an IC in sight).

Those were the days! no swapping parts, everything repaired to the smallest component."

Gary Mann had a similar experience with the resistors:

"My first job (after making the tea) was to replace the 10M ohm resistors that were used to

pre-charge the trigger tubes on the display cards and the registers as these tended to go high to 11M ohm. So that was 12 cards times 10 trigger tubes (120) plus all the tubes in the register, about 200 in all (brain numbing

stuff). The diode blocks (little black boxes) were also prone to leakage and needed replacement, but you had to measure each one, and still end up replacing 20 - 80. No swapping out boards in those days, it was

repair at component level, and quite often the repairs could be nearly half the cost of the machine. That's why most people had maintenance contracts."

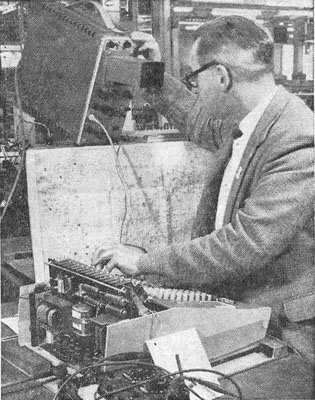

Setting up an ANITA using an oscilloscope.

John Rich developed a method of fault-finding for the display/counter boards:

"For about six months in 1961 I worked as a tester at Bell Punch, Fratton, Portsmouth, UK. It

was one of my first jobs after leaving the RAF. It was an interesting time and I well remember the job. I worked on the plug in boards which held the ring counter consisting of gas trigger tubes and a numericon display

tube.

The trigger tubes were unreliable and I developed a technique of winding down the high voltage supply to the card until it stopped running. The faulty tube was the one AFTER the one it stopped on.

It was my first

experience of production with printed circuit boards and I remember being fascinated by the Taylor machine which pre-formed and cut the bandoliers of resistors to go in the PCB."

George Steward relates:

"I worked at the ANITA factory in Portsmouth around 1962/3 as a prototype wireman. My job was to incorporate any modifications and introduce them to

the production line. This was quite time consuming as all the boards affected needed to be hand drilled and then hand wired. Once the production of drilled boards was on stream the Time/Motion people used to time me to

set the bonus rate for the girls on the production line. When I wasn't doing this I was recovering trigger tubes and Nixie tubes from faulty boards for re-use.

I do remember that the very early Mk VII machines would not work with the lid closed because it was too dark and that Hivac incorporated a 'night light' in the XN3 trigger tubes used in that model. That explains why there are 5 leads from a device which only needs 3 to work, the remaining pair were for the night light. [This is a problem with the discharge not initiating because it needs a little ionisation in the gas in the tube to get started, and light can provide this ionisation. It was cured by mounting a fourth electrode in the switching tube, connected through a high value resistor (as mentioned above) to a high voltage in order to 'prime' the ionisation in the gas.]

The girls on the 'Final Test' benches were so good that they could beat the machine! If they got fed up with testing the machines they could leave the company and take jobs as ANITA Operators in the office world and virtually name their own salaries. Obviously we had a high turnover of testers!"

John Clements worked as an engineer at Sumlock Comptometer from 1958 through to 1978, and worked on all the models from the Plus Adder with the black handles on the side of the case up to the ANITA Mk 12 and on to the LSI models.

He relates: "I worked in the Clerkenwell Road for about 3 years and then got a transfer to the Ealing office at Hanger Lane. I worked there until I got married and then I moved up to Norwich office.

I had a wonderful time with Sumlock and some of the engineers I worked with are as follows:

Clerkenwell road - Paddy McLaughlin,Dennis Dyer, Tony Bell, Ted Grist.

Ealing - Roland Tippings, Dave Woods, George

Dunkley.

Norwich - Norman Williams, Bob Doig, Mike Cole.

There are more of course but I can't remember their names."

Mike Denman tells of his experiences as a Service Engineer: "I started work for Sumlock in October 1971, at the tender age of 19. I moved down from Hull to take the position of Trainee Service Engineer, working in the Central London Service Department, on the 4th floor at 105 Clerkenwell Road. I was given the job by Brian Jackson, who was the District Service Controller at the time. I remember that the wage of £26 a week was a fortune and more than most of my family earned and I was glad to be working after six months on the dole. Unemployment was particularly high right then.

Because the next available ANITA Mk8 training course was in January, I was set to work in the panel repair department, fixing faults on ANITA LSI boards. This was not particularly skilled, as most of the faults tended to be common. The IC board was the worst and often involved taking a guess at which of the four chips was causing the problem.

At that time, the Panel Repair department was relatively new and was in the process of being moved to new premises in Frogmore Road, Apsley, on the outskirts of Hemel Hempstead. This was also where engineer training was to take place.

During 1972, I attended courses on the Mk8, Mk9/10, Mk11/12 and IC machines at the Hemel training school. The training was first rate and I recall that the Mk8 course lasted about three weeks or maybe more. Ian Partridge could well have been the instructor on these courses. We were put up in local hotels in the surrounding villages, such as the Bobsleigh at Bovingdon, and worked from lunch time Monday to lunch time Friday, when we collected a healthy expenses payment.

What fascinated me, was the depth of the training. We were taught everything about how the units worked and would be expected to isolate a fault down to the component causing the problem and replace it in the customer's office. To discover that the Mk8 worked in the same way as a mechanical drum calculator and performed division by subtracting one number from another until it went negative was a revelation. It made a lot more sense than anything I had learned at college.

After the first couple of courses, I was allocated to the City side of the workshop at Clerkenwell and was sent out in one of the company's blue Vauxhall Viva HA vans, to repair customer's machines. Sometimes it was the older machines, such as the Mk8, but more often it was to repair the LSI range, which were selling in great numbers and many fell off desks, generating plenty of work.

During this period I remember a number of labour disputes, mainly over wages. These resulted in short periods on strike. Inflation was running between 15 and 20% and everyone was trying to catch up. The union shop steward at Clerkenwell was a chap called Tom Foley and because of closed shop legislation, we were all members of ASTMS, the Association of Scientific, Technical and Managerial Staffs. They looked after us very well, but there were some pretty obvious 'restrictive practices' in place such as a maximum daily workload of eight field service jobs. This might have been a lot to do if you had a large rural area, but in the City, you often got clear by mid-day.

The ANITA Business Computer was launched in 1972, and by '73 the management was looking to set up a Systems Division to manage the servicing of this unit and the newly acquired Farringdon 1010 word processor. I moved to this new department, enticed by the offer of a company van and also re-located to the Finchley branch, at that time in Northway House, Whetstone.

The area we covered was quite large. Apart from North London, we also covered Herts, Beds, Bucks, Cambs, and Northants. During holidays I often crossed over to other areas to provide cover there too. From Northway House, we worked in parallel with the Calculator and Comptometer service departments.

We later re-located to Viatron House in Finchley High Road. The sales department also operated from the same building and the sales team, headed by John White, began to work form there instead of their old offices in central London. By this time, probably early '75, Rockwell was in control and we had a new Managing Director named Barry Ofield."

There are further experiences of Mike Denman told in the section Demise of Anita and Bell Punch.

Robert Rudd reminisces: "I worked for Sumlock Comptometer for 5 years in the 1960s as a field service engineer on the Anita Mk 8.

A most unreliable machine to today's

standards. The gas filled trigger tubes had a short life. The majority of the machines would only have 12 month's use before failure.

We had a little box with a rotary switch and resistors, the connection to this would be to a fuse cartridge that had blown.

Inserting this in the fuse socket at the rear would enable us to reduce the high tension supply to the

machine.

If any trigger tube failed an the low settings, we would replace that as well as the failing trigger tubes at normal voltage.

By doing this, it prevented many "call backs" following a repair. This was

not adopted officially by Sumlock Comptometer.

We had trouble with the "Long tail" resistors feeding the -125 volts to the "Night Lights" on the trigger tubes.

These were a high value resistor 20 Megohm if I remember.

They

used to go Open! and put the night light out. We had to replace all the resistors, a long job with a soldering iron.

The Constant voltage transformer was a clever idea.

It ran at hysteresis saturation so if the voltage increased or decreased the output would stay the same.

It was combined with the capacitor at

the side of the transformer. You may notice a gap in the iron yoke.

Happy Days!!!!!!"

The Bell Punch Company & the Development of the Anita Calculator

< Previous page Next page >

Text & photographs copyright © 2002 - 2023 Nigel Tout, except where noted otherwise.